Choosing induction welding equipment for your business is important. You need to think about tips that help you reach your goals. You want to spend money wisely. The equipment should match your production needs. It should also meet your technical needs. For example, a metal company had delays. Their supplier could not make enough products. An automotive company got better results. They improved efficiency by 20% after getting new equipment. Material quality is important too. Workshops with bad machines had breakdowns. They also had expensive repairs. Use expert tips when buying equipment. Think about your own work situation. This helps you avoid mistakes. Canroon is a trusted partner. They give good advice and reliable solutions.

Key Takeaways

Think about what you need for welding. Know the materials you use and how much you make. This helps you pick the best equipment.

Pick equipment that fits your business size. Portable units are good for small jobs. Stationary machines are better for big jobs.

Look at how much energy the machine uses. Machines with strong inverter power factors save money. They also help the environment.

Buy from a supplier you can trust. A good partner like Canroon gives support and training. They also offer equipment you can count on.

Get machines with automation features. These features help you work faster and make fewer mistakes. They help your business get bigger.

Assess Your Welding Needs

To pick the best induction welding equipment, you must know what you need. Think about the materials you use. Also, think about how much you want to make. Look at what you need for each job. If you check these things, you can avoid spending too much money. This helps your business grow and keeps your investment safe.

Material Types and Thickness

You should know what materials you weld. Induction welding equipment works with many metals and thermoplastics. You can weld thick steel pipes. You can also weld thin aluminum sheets. The equipment can handle many thicknesses. Induction welding does not depend much on material properties. You can weld different metals and thermoplastics without changing your process. You get strong welds even with hard materials.

Tip: Always look at your equipment’s specifications. Make sure it fits the thickness and type of material you use most.

Production Volume

How much you make affects what equipment you need. Small workshops may need small machines. Big factories need machines for lots of work. Ask yourself some questions:

Will you make more products later?

Do you need equipment that can grow with your business?

How many times will you use the machine each day?

A system that can grow lets you make more without buying new machines. Think about costs for the future. Saving energy and easy repairs help you save money.

Scalability: Can the system grow with your needs?

Compliance: Does it follow rules now and in the future?

Innovation: Is the vendor working on new technology?

ROI: What does it cost over time, including energy and repairs?

Vendor Support: Does the vendor help after you buy and offer training?

Application Specifics

Every business has its own welding needs. You might need to weld big or odd-shaped parts. You may need strong seals. Induction welding equipment uses radio frequency current. It heats the joint fast and well. This works for many shapes and sizes.

Here is a table that compares common preheating methods used in factories:

Induction welding equipment has many good points. You spend less on supplies because you can use insulation again. It is easy for workers to set up and change. You get strong welds even when the job is tough.

Induction Welding Equipment Types

Main Categories

There are different kinds of induction welding equipment. Each kind works best for certain jobs and business sizes. Here are the main types:

Portable Induction Welders: These machines are good for repairs and small shops. You can carry them and set them up quickly.

Stationary Induction Welders: These machines are made for factories and big jobs. They have more power and can do larger work.

Modular Welding Systems: You can change parts and tips for different materials. This makes the system flexible.

Tip: Choose a type that fits your workspace and project size.

Best-Use Scenarios

You should pick equipment that matches your work needs. Some machines are better for making lots of products. Others are good for small jobs or special tasks. The table below shows features that help in busy places:

If you have a big factory, you need equipment that works fast. High-power machines save time and make fewer mistakes. For small shops, portable or modular machines may be better.

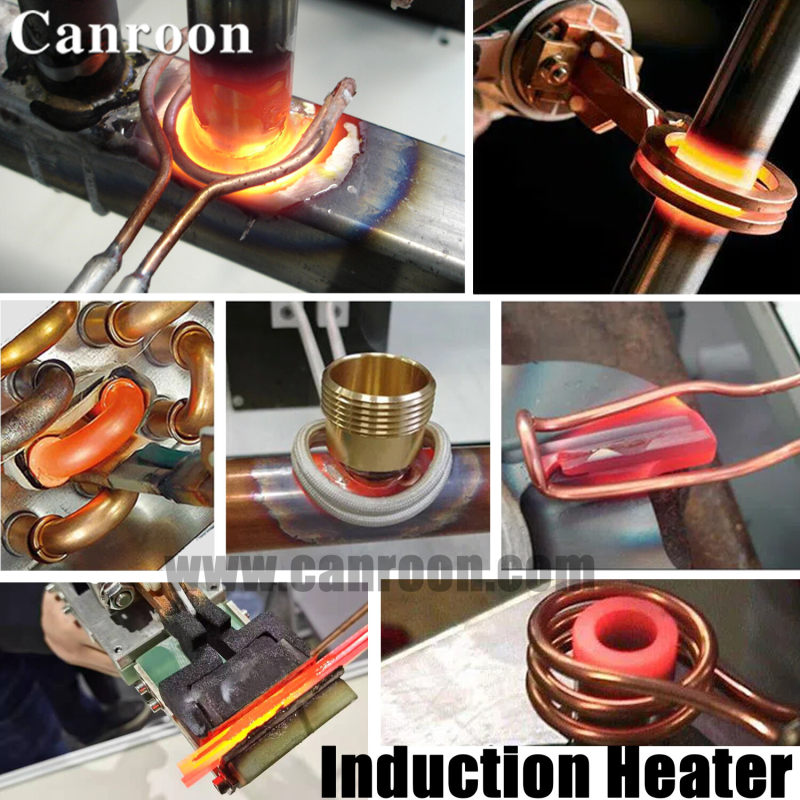

Canroon Solutions

Canroon has induction welding equipment with smart features. You can weld copper tubes for HVAC systems very well. The modular gun lets you change tips for different jobs. You can use it by hand or with controls for better welds. Canroon uses strong tungsten and copper tips. These last longer than steel tips.

The table below compares Canroon’s equipment with other brands:

Canroon’s induction welding equipment helps you follow safety rules and work faster. You can use their machines for big or small projects.

Power and Efficiency

Power Output Selection

You need to choose the right power output for your welding equipment. Output power means the load power of the machine. Oscillating power is about 60% of the actual output power. If you pick a higher power output, you get faster heating speeds. You also pay more for the machine. You should look at your heating needs. If you weld thick metals or work with large parts, you need more power. If you work with thin materials, you can use less power. Balancing speed and cost helps you make a smart choice.

Tip: Write down your most common jobs. Check the thickness and size of the materials. This helps you decide how much power you need.

Energy Efficiency

Energy efficiency saves you money and helps the environment. Some models use less electricity and work better. You can look for machines with a high inverter power factor. These machines waste less energy. You also want control modes that keep the temperature steady. The table below shows a model that works well and saves energy:

You can use this model for many jobs. It works with copper, stainless steel, and aluminum. It keeps the temperature steady and uses less power.

Power Supply Compatibility

You must check if your power supply matches the machine. Some machines need a special voltage. Others work with standard shop power. If you use the wrong supply, the machine may not work. Always read the manual before you buy. Ask your supplier if you have questions. You want a machine that fits your shop and does not need extra changes.

Note: A good supplier will help you pick a machine that matches your power supply. This saves you time and money.

Automation and Integration

Automation Features

Automation can make welding faster and safer. Many new machines work with robots and PLC systems. These systems help build big assembly lines. Sensors control things like frequency, power, and pressure. This keeps welds strong and even. Some machines use robots to load and unload parts. You can change settings for each batch with one click. Automation collects data during welding. This helps you track jobs and improve your work.

One-click changes save time when switching jobs.

Data collection shows how each weld works.

Tip: Automation helps you make more products with fewer errors.

System Compatibility

You need to check if your new machine fits your setup. Every factory has different needs. Look at power and frequency limits. Check if the coil design matches your parts. Make sure your cooling system can handle the heat. Your machine should connect to your PLC system. Recipe management helps keep quality high. Temperature feedback lets you change settings fast. Communication protocols must match your other machines. Your workspace should fit the new equipment.

Note: Always ask your supplier about system compatibility before buying.

Adjustable Settings

Advanced machines let you change many settings for better results. You control output current, frequency, and power. You set the speed for each job. You adjust coil turns and air gaps for different parts. You can change the distance from the coil to the surface. These settings help you weld different materials and shapes. You get strong welds every time.

Tip: Adjustable settings help you work with many materials and job sizes.

Quality and Safety

Safety Features

It is important to keep everyone safe when using welding machines. Makers build machines with safety as a top goal. There are rules for how much electromagnetic field workers can get. OSHA makes these rules to keep people safe. Machines have grounding to stop electric shocks. Workers wear gloves and goggles to protect themselves. These steps help stop injuries and keep the shop safe.

Here is a table that lists safety features:

Tip: Always make sure your machines follow safety rules before you start.

Reliability and Certifications

You want machines that work well every day. Good machines help you finish jobs on time. Look for ISO and CE certifications. These show the machine follows strict rules. Certified machines get tested many times. You get better work and fewer problems. You also follow laws and industry rules. This keeps your business and workers safe.

ISO means the machine follows world safety and quality rules.

CE shows the machine meets European safety standards.

Regular checks help keep machines safe and working well.

Canroon Quality Standards

Canroon makes machines that last a long time. Their parts are strong and reliable. Canroon tests each machine before sending it out. You see clear safety labels on every machine. The company follows ISO and CE rules. You get help and training to use machines safely. Canroon’s team helps you fix problems fast. You can trust their machines to keep your shop safe and working well.

Note: Picking a trusted company like Canroon helps you reach safety and quality goals.

Portability and Flexibility

Portable Equipment Options

You need portable induction welding equipment for different places. Portable units help you move fast and set up quickly. There are many types to pick from. Each type works for a certain job and budget.

Here is a table that shows popular portable choices:

Portable handheld units are best for quick fixes and small jobs. You can carry them without trouble. Midsized units help you do more work faster. They give you more power and last longer. Industrial-grade units have smart tools. You use them for big jobs and automation. They cost more but work very well.

Tip: Always check power and how long it can work. Pick a unit that fits your job.

Fieldwork and Mobility

You sometimes need to weld outside your shop. Fieldwork means you take your equipment to new places. Portable induction welders help you work on-site. You can fix pipes or machines far away. You save time because you do not bring parts back.

Look for these things in portable equipment:

Light design so you can carry it

Quick setup for fast work

Works with batteries or generators

Strong case to keep it safe

You can use portable welders in building sites, shipyards, and repair places. You finish jobs faster and stop delays. Induction welding is safer because it does not use fire.

Note: Pick equipment with tough cases and simple controls. You work safer and better outside.

Cost Considerations

Initial Investment

You need to look at the price before you buy welding equipment. The cost depends on the size, power, and features of the machine. Portable units cost less than large factory systems. You pay more for machines with automation and smart controls. Some suppliers offer payment plans or discounts for bulk orders. You should ask about extra costs like installation and training. A clear budget helps you pick the right model for your shop.

Tip: Always compare prices and features. Ask for a quote that includes everything you need.

Maintenance and Operation

You save money over time with easy repairs and low upkeep. Most welding equipment uses simple parts that you can replace quickly. You do not need special tools for most fixes. The annual maintenance costs stay low because spare parts are easy to find. You spend less time waiting for repairs, so your work does not stop. Regular cleaning and checks keep your machine running well. You should follow the supplier’s guide for best results.

Long-Term Value

You get strong benefits when you choose induction over traditional welding. Induction systems work faster and use less energy. You finish jobs up to 70% quicker. These machines reach up to 90% efficiency, while older methods only reach 60%. You pay less for electricity and repairs. Most users see a payback in 2 to 5 years. You also get better welds with fewer mistakes. Precise temperature control means less scrap and fewer defects.

High efficiency saves energy.

Fast processing boosts output.

Lower costs shorten payback time.

Fewer defects protect your profits.

You should think about the total cost of ownership. This means looking at the price, upkeep, and savings over time. Smart choices help your business grow and stay strong.

Supplier and Support

Choosing a Reputable Supplier

You should pick your welding equipment supplier carefully. The right supplier helps your business do well. They make sure you get good results. Here are some steps to help you choose:

Write down what equipment you need and how many.

Search online and ask people in your industry for advice.

Make sure the supplier has the right certifications and meets standards.

Ask for quotes and check if the prices fit your budget.

Choose a supplier who answers your questions and helps you.

Tip: A trusted supplier like Canroon helps you feel safe and avoid mistakes that cost money.

After-Sales Support

It is important to get good support after you buy your equipment. Good support helps with repairs, warranties, and questions. A reliable supplier fixes problems quickly. You save time and money because you do not wait long. You also get tips to keep your machines working well.

Note: After-sales support keeps your equipment safe and helps you fix problems fast.

Training and Service

Training and service programs teach you how to use your equipment. Top suppliers offer many kinds of help. Here is a table that shows common services:

Training and service programs help you get better results. You learn to use your equipment and keep it working well. A good supplier helps you at every step.

Expert Consultation

Industry Expert Advice

Industry experts can help you make better choices. They know what equipment works for different businesses. Experts look at your goals and needs. They help you pick the right equipment. You get advice about safety and saving money. Experts also teach you how to set up machines fast. They show you how to use the equipment.

Here is a table with expert tips and their benefits:

Tip: Ask experts how to keep your shop safe and working well.

Custom Recommendations

Experts give advice that fits your business. They look at your work and suggest equipment for your jobs. You get solutions for your industry, like metals or plastics. Experts help you find machines that use less energy. They help you pick equipment that works better for you.

Here is a table showing how experts match advice to your needs:

You should talk to experts before you buy anything. They help you avoid mistakes and get the most for your money. You get advice that helps your business grow and keeps your work safe.

You can make smart choices for your business by following a clear process. Start by picking the right frequency for your job. Adjust the coil design to match your needs. Check that the copper tubing wall thickness is strong enough for good results. Talk with trusted suppliers like Canroon to get advice that fits your goals. Begin your equipment selection journey today and help your business grow.

FAQ

What are butt welding machines used for?

Butt welding machines join two metal pieces together. The pieces are joined end-to-end. These machines make strong and smooth joints. People use them in pipe making and metal shops. They are also used for fixing things.

How do butt welding machines improve production efficiency?

Butt welding machines heat and join metal fast. You do not need extra stuff to weld. This saves time on each job. The results look the same every time. You can make more products and waste less metal.

Can butt welding machines handle different metal thicknesses?

You can use these machines for thick or thin metal. You change the settings for each job. Butt welding machines work with steel, copper, and aluminum. You get strong welds no matter the thickness.

Are butt welding machines safe to operate?

You stay safe if you follow the rules. These machines have shields and grounding for safety. You should wear gloves and goggles. Training helps you use the machine safely.

What maintenance do butt welding machines require?

You need to clean the machine often. Check the cables and connections for damage. Change old parts when needed. Follow the guide from the supplier. Simple checks keep your machine working well.

Tip: Always look over your machine before you use it. This helps stop problems and keeps your shop safe.

Sign up for updates